VETRERIA PACHETTI: THE INDUSTRY 4.0 REVOLUTION IN A SMALL GLASS WORKING COMPANY

2023

THE CHALLENGE

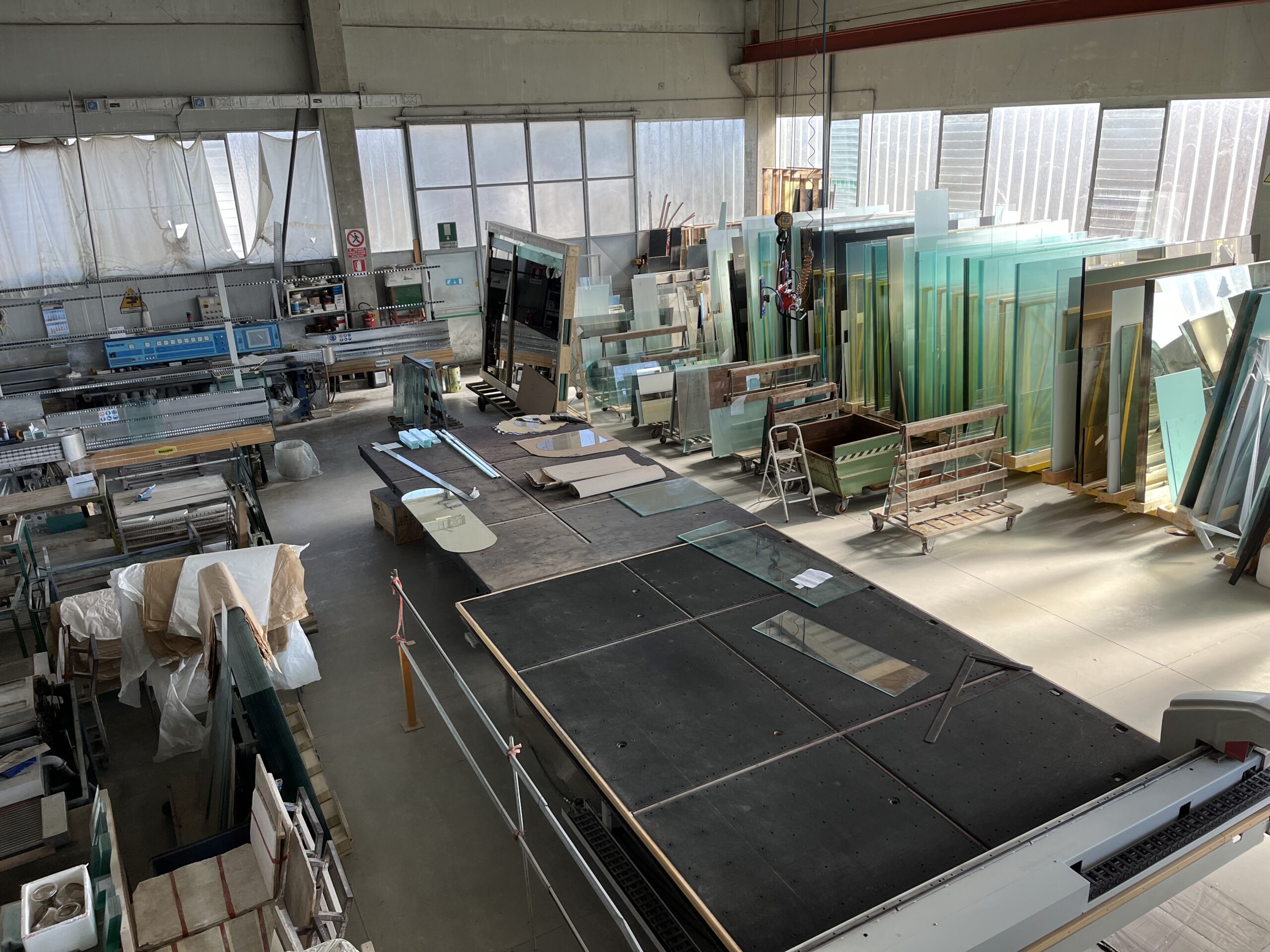

Vetreria Pachetti, which has been present in the Tuscan market for years, with ten employees, six of whom are in production, is a small family-run business that operates in the glass processing sector. In particular, it processes flat glass, supplying components for residential and store furnishings, as well as mirrors and artistic stained glass.

In order to optimize its production process, the company decides to digitize its fleet of machines by interconnecting the new MASTER BIESSE in 2021, taking advantage of the tax benefits of the Transition Plan 4.0: it is the beginning of a new way of working completely 4.0.

THE SOLUTION

The glassworks adopts as its digital factory system the MES component called SMARTCONNECTION, from BIESSE “powered by RETUNER®”: a production management system released in the version specifically designed for small and medium-sized manufacturing companies operating in the glass industry, whose main function is to connect production operators on any device to keep track of all production stages by enabling them to record activities, stoppages, production progress and anomalies.

BENEFITS

With the introduction of SMARTCONNECTION software, the company recognized a number of benefits including:

- Increased ability to plan job order processing due to its digitization and traceability

- Improved monitoring and control of the progress of the job order within the production process

- Optimization of delivery time management due to the operational overload to which the machine is subjected through the visualization of the processing schedule

- More efficient use of company resources

SMARTCONNECTION has turned the company’s production process around, so much so that Vetreria Pachetti wanted to extend the application to all production processes and maintain Industry 4.0 requirements by subscribing to the maintenance fee for new versions of the software.

“SMARTCONNECTION has allowed us to digitize the job order and know its progress at any time within the production process. In addition, the visualization of the processing schedule has allowed us to better manage delivery schedules always having in mind the so-called operational overload in which the machine is affected,” says Massimo Pachetti, owner of the company.