TONELLI WORKS Mechanical Workshops

2024

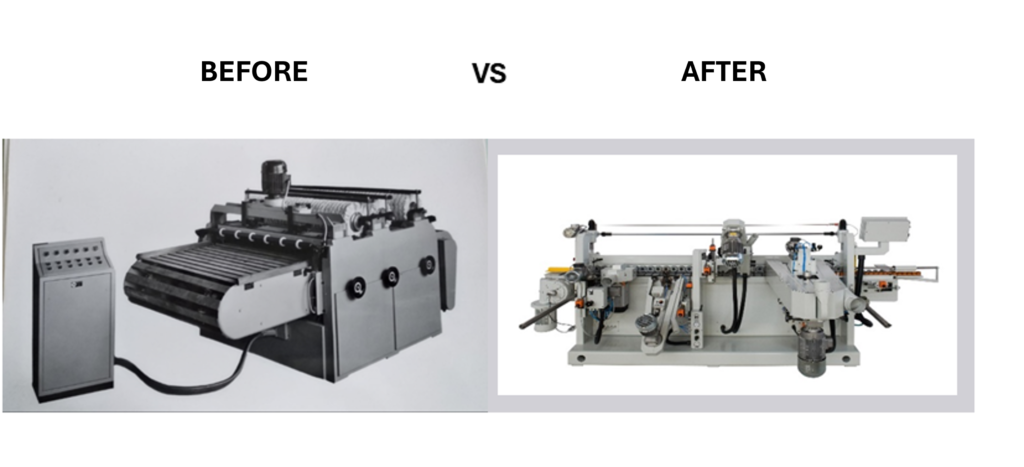

Tonelli is a historic company operating since 1952 in the province of Monza and Brianza (Italy) in the sanding machine sector, thanks to founder Mario Tonelli. In particular, the company produces:

- Double-shoulder roller sanding machines for profiles, jambs and doorframes

- Single-shoulder sanding machines for panels for the furniture industry

- Polishing machines for panel edges for the furniture industry

Every function performed by the various processing units is electronically controlled by a

state-of-the-art touch screen PLC that meets all the requirements of Industry 4.0

AN INDUSTRIAL FUTURE BASED ON SUSTAINABILITY AND DIGITIZATION

Nowadays, digitization and sustainability continue to be key factors for the competitiveness of manufacturing companies in the era of Industry 5.0. In this context, since 2021 TONELLI has chosen Orchestra as its partner to digitize its machinery and implement Industry 4.0 and 5.0 projects for customers in the manufacturing sector. For the Italian market, Orchestra offers machinery manufacturers a turnkey “Transition 5.0” solution, which includes both the technology to monitor energy consumption in relation to production and the services to manage practices and competencies, according to the directions of the new Italian Transition 5.0 Plan.

The “Transition 5.0” package that Orchestra offers TONELLI customers includes:

-the technology to ensure INDUSTRY 4.0 requirements.

-the integration with MID-certified energy meters to measure energy efficiency for TRANSITION5.0

-the complete practice management service from the submission of the application to the GSE to the final sworn report.

The use of Orchestra’s RETUNER® technology offers numerous advantages:

- TONELLI’s machines can easily be interconnected both with the ICT systems present in the company and with the rest of the fleet of machines and production lines of other manufacturers;

- The customer has at his disposal normalized and certified data that allow him to control, monitor and manage production in real time;

- BI functions, integrated into the MES component, return production performance, providing the entrepreneur with a tool to assess and manage the company’s competitiveness and resilience;

- new features in xMES, the extended version of RETUNER®’s miniMES, give the ability to measure the company’s sustainability goals from energy consumption and integrate the supply chain.

“Orchestra has given us a big hand in the implementation of interconnection 4.0 projects and a valuable commercial leverage to sell our machinery in Italy and worldwide.” says Mirko Castelletti Owner of TONELLI WORKS today.