TOGETHER WITH ORMAMACCHINE PROJECTED TOWARD A SUSTAINABLE AND DIGITAL INDUSTRY

2024

Ormamacchine: in the field of hydraulic presses for more than 50 years

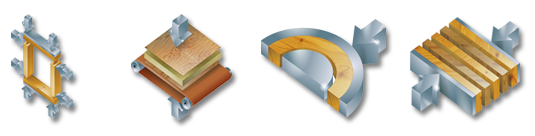

Ormamacchine S.p.A. is active in the production of machinery intended for wood processing, and in particular specializes in the pressing of wood panels: from classic solid to the latest findings in the field of agglomerates, and their substitutes.

The plants, built with the customer’s needs always in mind, are distinguished by the search for versatility and ease of use even in the case of rather complex plants. The acquisition and development of the most modern technologies, both from the point of view of construction and application, combined with the search for medium/high quality standards for its product make Ormamacchine stand out in its sector as one of the leading companies on the national and international market. A production capacity of about 900 systems/year, the employment of about 130 people and the use of 5 production units, all in Italy, are the company’s current numbers, which alone guarantee professionalism, competence and experience.

While not neglecting the wood sector, Ormamacchine in the last 20 years has diversified its production of hydraulic presses by going into other fields such as composite materials, polyurethane panels and plastics (Solid Surface) with remarkable success. Quality control, innovative spirit, attention to the customer and his problems, and a great competitiveness make Ormamacchine the ideal partner for all companies, from the smallest family-run to those that are part of industrial groups.

For this type of plant and machinery, it is essential to have Industry 4.0 and, now, 5.0 services provided on a turnkey basis. To this end, in 2020 Ormamacchine chooses Orchestra as its partner to digitize its machines and facilitate manufacturing customers’ access to the incentives of Transition 4.0 and 5.0 Plans.

Specifically, Orchestra offers Ormamacchine customers a comprehensive “Transition 5.0” package, which includes:

– technology to ensure the requirements of INDUSTRY 4.0

-integration with MID-certified energy meters to measure energy efficiency for TRANSITION5.0

– The complete practice management service from the submission of the application to the GSE to the final sworn report.

The adoption of RETUNER® technology offers numerous advantages:

-Ormamacchine’s machines can easily be interconnected both with the ICT systems present in the company and with the rest of the fleet of machines and production lines of other manufacturers;

-The customer has at his disposal normalized and certified data that allow him to control, monitor and manage production in real time;

-BI functions, integrated into the MES component, return production performance by providing the entrepreneur with a tool to assess and manage the company’s competitiveness and resilience;

-new features in xMES, the extended version of RETUNER®’s miniMES, give the ability to measure the company’s sustainability goals from energy consumption and integrate the supply chain.

“We have been cooperating with ORCHESTRA S.r.l since 2021 and would like to express our sincere appreciation for the fruitful and professional cooperation. Your expertise, dedication, and ability to understand and meet the needs of our mutual clients are critical to the success of the projects. Your team has demonstrated an excellent ability to develop innovative solutions, ensuring not only the meeting of deadlines but also the high quality of the delivered software. Your attention to detail and promptness in resolving issues enabled us to meet challenges with confidence and peace of mind. Your professionalism and passion for the work are a guarantee of excellence for us.” Said Azzimonti Fabrizio, Owner of ORMAMACCHINE S.p.A.