OMV VISMARA CHOOSES ORCHESTRA FOR DIGITAL TRANSFORMATION

OMV Vismara specializes in the production of flat glass processing technologies. From a small enterprise, the company has rapidly grown without ever changing its identity, to the point of internationalizing its market.

The centrality of the company is tailor-made. The most important prerogative is to be able to satisfy the customer in every possible need. OMV Vismara bases its solidity on a strictly Made in Italy brand, which, born in 1981, has grown steadily and is constantly growing. Among the many companies operating in the industry, OMV Vismara is one of the few companies with a solid continuous presence for more than 40 years.

Seeing is believing: It is certainly more reassuring to be able to see for yourself the products that are offered on the market. For this reason, the company offers the opportunity to learn about and test its technologies in a dedicated show room.

INDUSTRY 5.0: SUSTAINABILITY IN MANUFACTURING

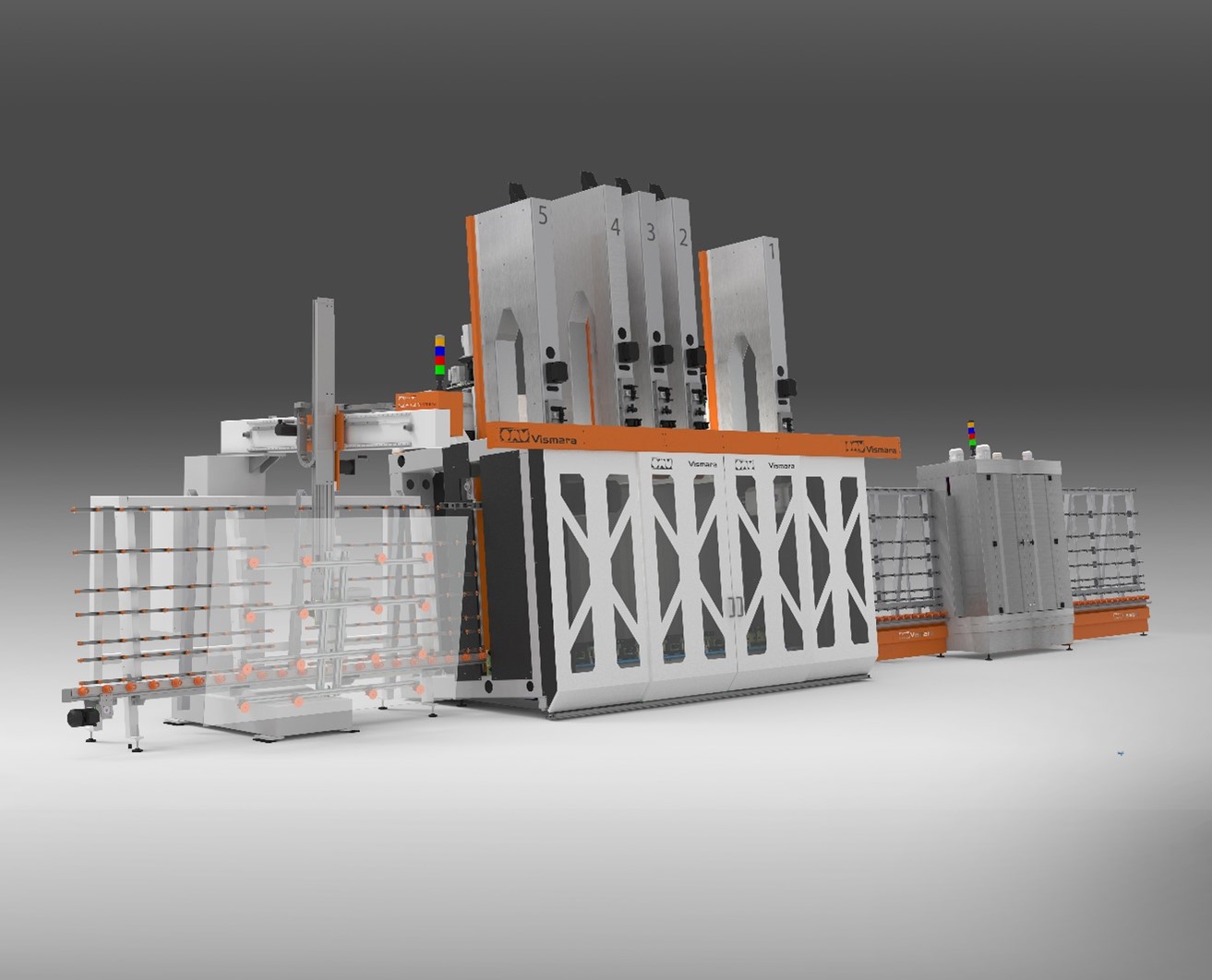

As a whole, OMV Vismara’s production range offers vertical drilling and boring-milling machines and horizontal drilling machines for processing flat glass. In addition, the company manufactures washing machines, Cartesian loaders and unloaders, grinding machines and filleting machines, which allow the customer to choose a single point of contact for the required processing line. The strength of OMV machinery lies in the peculiar attention, which accompanies the entire production phase of the machine: from its design up to possible service interventions.

In the current era of digitization, machines must be equipped with solutions that align with Industry 4.0 and, more recently, Industry 5.0 models, available in turnkey mode. Among the various technology solutions on the market, in 2022, OMV chooses Orchestra as a strategic partner to digitize its products and facilitate manufacturing customers’ access to incentives under the Transition 4.0 and 5.0 Plans.

Orchestra offers OMV’s customers a complete package called “RETUNERGY 5.0,” which includes advanced technology for monitoring production-related energy consumption, as well as paperwork and appraisal management services.

THE BENEFITS OF RETUNER®, THE ORCHESTRA’S SUITE OF PRODUCTS

The adoption of RETUNER® technology offers a variety of advantages that can be divided into 4 main points:

- OMV’s machines can be easily connected to both enterprise ICT systems and other machines and production lines.

- Customers have access to certified and normalized data, enabling them to control, monitor and manage production in real time.

- Business Intelligence (BI) capabilities, integrated into the MES system, provide information on production performance, giving business owners tools to assess and improve the company’s competitiveness and resilience.

- New xMES capabilities enable the measurement of corporate sustainability goals from energy consumption, while also integrating the supply chain.

WHAT PEOPLE SAY ABOUT US?

“Simple program for a single machine, which on request becomes expandable to several machines, even if from different manufacturers and interfaces with different management systems, already present within the companies that purchase the product,” says Mauro Vismara Owner of OMV VISMARA today.