Focus on: Industry 5.0, theory and real applications

October 19, 2023

Collaboration between man and machines, sustainability, resilience. These are some of the features of Industry 5.0. What are the opportunities for small and medium eterprises?

Let’s start with definitions. Industry 5.0 is the continuation of the digital transformation started by Industry 4.0. A path of innovation devoted to change the face of factory production and beyond.

If with the 4.0 revolution digital technologies have definitively entered the industrial world, the next step sees the affirmation of new paradigms. Without claiming to be exhaustive, we can identify three major themes.

The first one is the so called human-centric approach, which sees the worker’s wellbeing as the final objective of the entire process. The second major theme of sustainability is ideally connected to this. Today, companies must adopt circular economy and energy efficiency strategies to be competitive and generate a virtuous return for the community.

Finally, in a global context characterized by uncertainty, resilience represents the third major element on which manufacturing companies must base their business model.

Industry 5.0 technologies

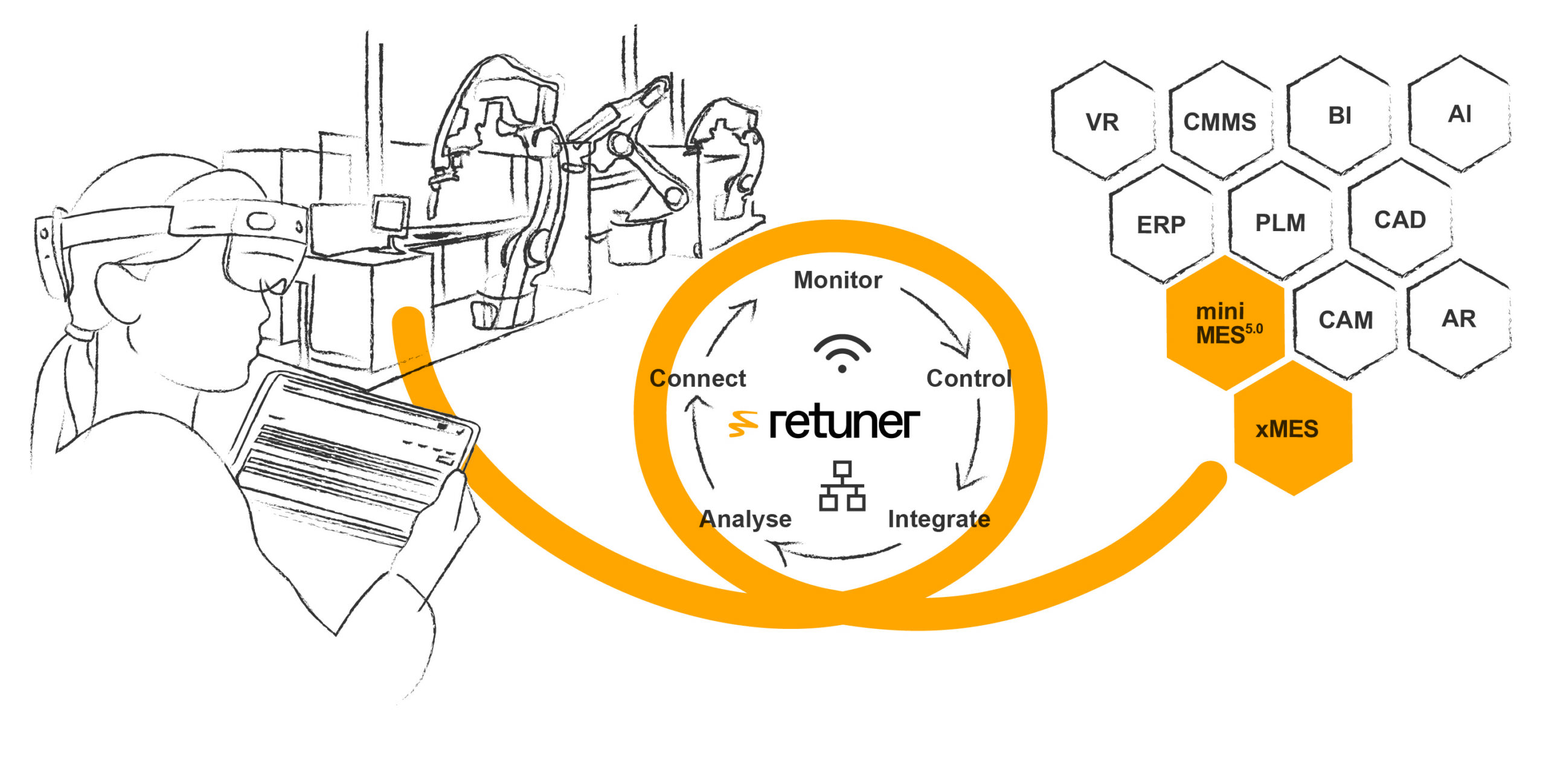

The transition from Industry 4.0 to Industry 5.0 is characterized by the integration of new technologies and above all new methodologies.

A first strong element is represented by the ever-increasing collaboration between man and machine. This is made possible by various technological assets, from Big Data to artificial intelligence to cognitive computing. The transition from human-machine interaction to human-machine dialogue has an important impact on the 5.0 factory.

At the same time, the evolution of digital networks leads to the convergence between IT infrastructures, OT (Operational Technologies) networks and ICT (Industrial Control System). This convergence is enabled by the creation of hybrid cloud computing and edge computing platforms, which shape cloud driven edge computing systems.

A further element on which to focus attention concerns real time machine-machine and machine-operator communication, enabled by the Industrial Internet of Things (IIoT). The transition to the 5.0 world allows for greater integration between companies’ digital platforms, connecting the entire company layout.

Industry 5.0 and SMES’s

Innovation always generates enthusiasm. The scenario we described in the previous paragraphs is promising. How to turn it into reality within small and medium-sized companies?

First of all, it is important to define the action parameter within which to implement 5.0 transformation strategies. This is possible starting from an analysis of the production layout, the objectives to be achieved and the potential critical issues.

The analysis allows us to find the best solutions in line with the company’s needs, through the integration of dedicated solutions, from MES to edge computing platforms. All within an open and scalable architecture, capable of enabling dialogue between technologies and systems from different suppliers.

In this way it is possible to open the doors to Industry 5.0 and create a virtuous path of growth and innovation.

Immagine via Unsplash